Composite end use

Composite end use materials

We provide the whole accessories and materials necessary for the manufacture of composite piece ( felt, plain, peel ply ). It gets working by damp way, infusion or pre preg.

A composite fabric is the result of association of several raw materials with different properties. It allows to create an homogeneous product which end properties are upper to each original properties of compenents taken alone. It usually combines a die and a reinforcement to create a laminate. We can consider that die role is to ensure cohesion between all reinforcements and that fibers supports efforts which fabric is supposed to resist.A/ Reinforcements

1. Fiber matt

Assemblage of short fibers ( glass, carbon, etc... ) with help of a light binder.

2. Yarns/ filaments

This is the most common typr of reinforcement. It can have a large diameter and be made of big monofilaments, this is Roving. It can be thin and made of fine monofilaments, this is silionne.

3. Les nappes

Al yarns are deposed in a parallely way and in only on direction. The repartition of yarns is clearly anisotrope. Reinforcement is 100 % unidirectional.

4. Fabrics

Continuous yarns are layed according to two perpendicular directions ( warp & weft ) and interwoven according to different patterns which allow to distinct weave style of the fabric ( plain, twill, satin, etc.. ).

5. Multidirictionals

These are an amount of filaments layed in multidirection and sewed each other to make a piece.

B/ Resins

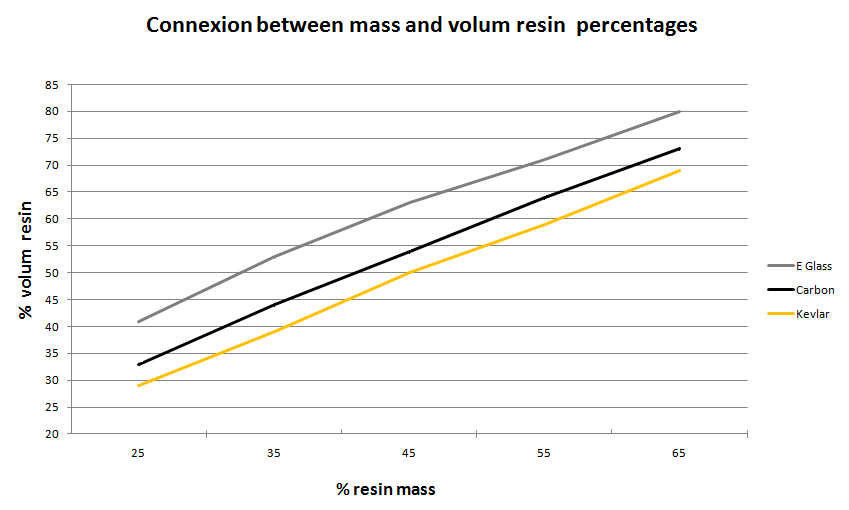

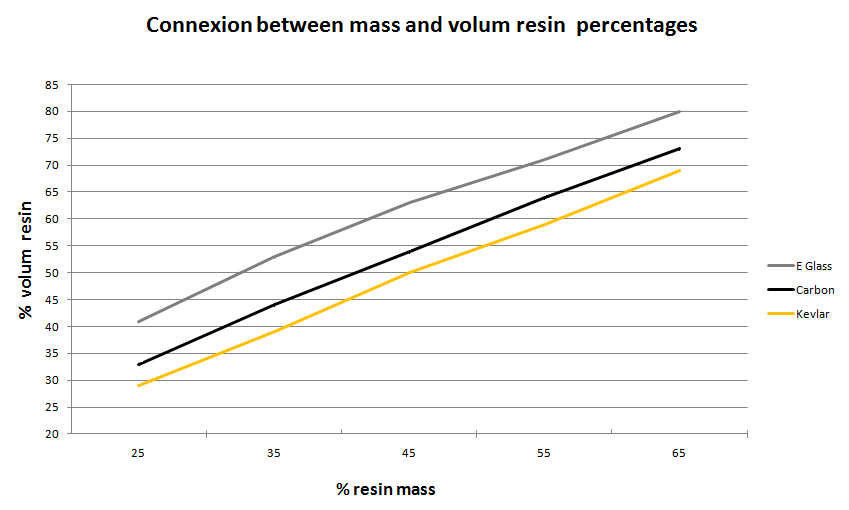

A die/ matrix is the resin system connecting different coats of reinforcement. It is important leting resin enough to assure the connexion between fibers and coats.

Minimum quantity :

60 % REINFORCEMENT in VOLUME

40 % RESIN in VOLUME

40 % RESIN in VOLUME

Polyester, epoxy resins are mostly used but we can also find vinyl-esters resins.

However, we stay at your attention to help you and give you advice for glass, carbon and aramid fabrics.

Don't hesitate to contact us for further information.

| Famille | ||

| Domaine |

| Référence | Largeur | Composition | Poids gr/cm | Armure | Fils/cm | CPS/cm | Traitement | Propriété |

|---|---|---|---|---|---|---|---|---|

| 20320 | 1000 | verranne 660 TEX | 500 | taffetas | 3.8 | 3.8 | test |